Bolted joints exposed to dynamic loads or pure vibrations are

very likely to loosen if movements under the head/nut occur. This

problem forces designers to invent different kinds of bolt securing

methods. Mentioning all known securing systems would lead to a very

long list.

The main principles for bolt securing are:

*

Design the joints with a large ratio between clamping

length/diameter. The bolt will be relatively slim which makes it

more flexible and the surface contact under the head/ nut will be

maintained. Furthermore the bolt has to rotate longer before the

clamping force will be lost. This method is an expensive design.

Extension sockets and of course long bolts have to be used.

*

Castle nut or the head/nut secured with a tab washer or locking

wire. These securing systems involve relatively complicated assembly

and disassembly. Unfortunately they cannot provide firm locking and

part of the bolt force is lost.

* Increase of friction under the

head/nut or in the thread. Locking nuts with increased friction in

the thread have the advantage that they cannot completely loosen by

themselves. Unfortunately, the increase of friction is not effective

at high bolt tension. Non-free-spinning threads makes assembly

laborious.

* Friction towards the material is increased by

providing heads/nuts with serrated surface, often in combination

with a flange in order to increase the surface contact and the

friction force. This method usually requires a considerably higher

torque. Upon assembly and mainly disassembly a strong scratching

towards the material will occur. However, a large serrated surface

will prevent the bolt/nut from loosening.

* Friction washers with

serrations work as described above, however, provide easier storage

of fasteners.

* To use adhesives in the threads has become a

very common method. It requires minimum storage of fasteners but

does have some other requirements. In order to obtain an effective

locking effect the surfaces need to be cleaned before assembly.

Service and maintenance can be troublesome since disassembly is not

easy and cleaning of the surfaces is a must before reassembly. Using

adhesives results in a considerable increase in friction with great

variation in clamp force.

Applying adhesives in the threads is an

ineffective method when service is required. Furthermore, a curing

time is required to provide an effective locking effect. At an

emergency repair the adhesive may not be available.

Make the bolt self-locking

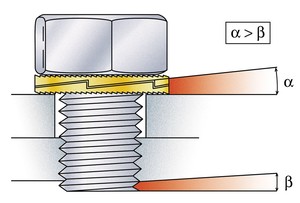

Nord-Lock is a pair of washers with wedge locking action

according to DIN 25 201. This method uses tension instead of

friction. On one side the washers have cams with a greater rise than

the pitch of the bolt.

In addition, there are radial teeth on

the opposite side. The washers come pre-assembled in pairs cam face

on cam face. When the bolt and/or nut is tightened, the teeth grip

and seat the mating surfaces. The washer is locked in place,

allowing movement only across the face of the cams. The tension

created makes the bolt/nut self-locking.

Vibration tests using

the Junker method and test results from the German TUV confirm the

practical experiences that Nord-Lockâ does provide a secure locking

method for bolted joints exposed to dynamic loads and vibrations. A

bolt, which has to increase tension in order to loosen, cannot

possibly loosen itself.

Nord-Lock AB has been producing the

washers since 1982. The company perform a customer service by

checking torque - load ratios for most kind of joints and run Junker

tests in the range of M3 - M27 bolt size. The joint consists of two

plates with a needle bearing in between. The bolt tension is

measured during the vibration test. When opening a bolt locked with

Nord-Lockâ there is a small increase of tension during the cam

overriding. Even at very moderate preloads the Nord-Lockâ washers

provide a secure and vibration proof locking.

The test diagram

(Fig. 2) shows the bolt tension during vibration testing of some

common fasteners. The tension will drop completely for non-secured

nuts and most of the tension will be lost for nuts with added

friction to the thread or with spring washers. Some of these may

hold better but it is all depending on the friction. A lubricated

thread makes the nut turn loose quicker than when the surfaces are

dry.

All vibration tests show a positive result when using

Nord-Lock. Some of the initial tension gets lost due to settlements

since the test is rather brutal with an amplitude of ±0.3mm. The

locking function proves itself when the nut is being un-tightened

with a wrench. A clear increase of tension is registered. Vibration

tests with the same bolt and mating material as an actual case

provide a good proof of how safe the joint will be even under worst

circumstances (vibrations, dynamic and shock loads).

A test on

UNF 5/8 bolts with and amplitude of ±1mm is so brutal that tab

washers will open due anti-clockwise turning of the bolts and there

is a complete loss of clamp load. The same test with Nord-Lockâ

washers shows only a minor loss of clamp load caused by settlements

in the thread but there is no off-turning motion.

The Nord-Lock

washers can be used on long holes as well. The edges of the long

hole can be deformed by using the standard dimension of washers with

a regular nut. This combination of fasteners leads to slightly

greater settlements than if a washer with larger outer diameter is

used. Therefore it's recommended to use the special washers with a

larger outer diameter in combination with a flanged bolt/nut.

To

assemble a bolt on powder painted surfaces has become common. Even

here, Nord-Lock secures safely. Comparative Junker vibration tests

with painted and unpainted surfaces show a limited difference of

settlement.

Using a standard dimension washer with a regular nut

on a painted surface the preload in the joint will decrease slightly

due to settlements not only in the thread but also in the layer of

paint, however, the locking effect remains positive. Using a washer

with a larger outer diameter in combination with a flanged bolt/nut

will minimise the settlements.

Advantages

For machinery, which requires regular service and maintenance,

Nord-Lockâ is the optimum solution of bolt securing. Bolted joints

secured with Nord-Lockâ are easy to untighten with general tools and

mounting elements can easily be lubricated before reassembly.

Normally lubricated bolts loosen easier than if the friction is

higher. Lubricants in combination with Nord-Lock do not jeopardise

the security. The bolt is not only safely locked but also easy to

open and the fasteners are re-usable.

When securing a stud bolt

it is normally locked in the taped hole with an adhesive and the nut

is often of jamming type. This method is complicated. Difficult

repair work has to be done if the bolt should break from fatigue. A

stud bolt with the same pitch in both ends will not turn by itself

and the nut can simply and safely be secured to the material with

Nord-Lock and any repair job will be easy.

Thanks to the fact

that Nord-Lock washers do not rely on friction they will not loose

their locking effect due to lubrication. Lubrication is always

important to reduce friction upon assembly. With less friction, less

torque is required to obtain the desired preload. Besides that the

spread of the preload will be minimised by more controlled

friction.

The washers are available in through hardened steel

either yellow zinc chromated, Dacromet or Delta coated and also in

stainless steel 316. The stainless steel washers can be used at

temperatures up to 500ûC without any reduction in performance. This

is an important factor for many applications such as turbines and

engines.

The washers come in pre-assembled pairs, which makes

assembly easy and safe. The standard dimension range for steel

washers is M3 to M130 and for stainless steel M3 to M80. They lock

standard and high grade bolts.

Ultra Dynamics in the United

Kingdom is a manufacturer of rail retarder systems used in

marshalling yards worldwide. These hydraulic retarders are at set

distances along the track to bring the train to the correct speed

for that part of the marshalling yard. Due to the fact that the

retarders are exposed to high/low frequency vibrations, shock loads,

pressure loads and daily temperature changes, Nord-Lock washers were

chosen as the standard fastener. Friction style fasteners were ruled

out, as the dynamic loads cause transverse movements in the stud

thread and under the nut leading to severe loss of friction making

the risk of slackening too high.

In order to achieve an optimum

of clamping force, lubrication of the threads and nuts is necessary.

With measures for lower friction, the locking methods based on

increased friction will loose their effect. Using Nord-Lock, which

locks by tension, in combination with lubricants will provide a safe

joint with high tension.

Another Nord-Lock user is VAE railway

technology in Zeltweg, Austria, a leader in the construction of high

speed switch points. Stable and precisely set tracks allow high

speeds up to 250km/h.

The tracks are being equipped with high

speed switch points. One location for Nord-Lock is the switch driver

responsible for the changing of points and the quick positioning of

the switch tong. This tong absorbs extreme dynamic loads, transverse

movements in the bolt head and/or nut leading to a severe loss of

friction. Nord-Locks wedge-locking effect safely and economically

solves the problem. The geometric design of the fasteners used

properly in a joint guarantees self-locking regardless of friction.

The bolt securing system was chosen after stringent tests were

carried out by different engineering bodies for use in the cab, the

chassis and the passenger compartments.

Alstom DDF in France is

installing Nord-Lock washer to secure bolts on structural and

traction connections in order to achieve maximum safety. The washers

have proven to solve loosening problems on rails, switches and

signal systems in Europe and in the US. |