|

|

|

|

|

|

|

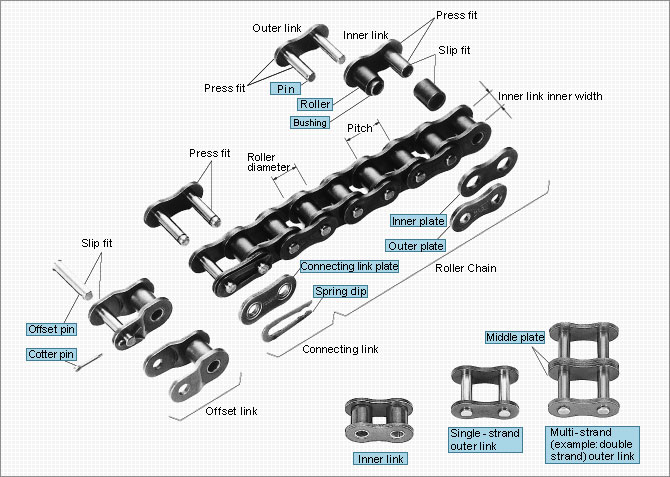

The

plate is the component that bears the tension placed on the roller

chain during transmission. Usually this is a repeat load, sometimes

accompanied by shock. The plate must therefore have not only great

static tensile strength, but also high fatigue strength, impact

strength, and dynamic toughness. |

|

The

pin is subjected to shearing and bearing forces transmitted by the

plate. At the same time, it forms a load-bearing part, together with

the bushing, when the chain flexes during sprocket engagement.

Therefore, the pin needs wear resistance other than shear strength,

bending strength and toughness. |

|

|

|

The

bushing is subjected to complex forces from various parts. It must have

high impact fatigue strength, as it bears repeated shock load,

especially when the chain engages the sprocket. Acting as a bearing

when coupled with the pin, it must have wear resistance. |

|

The

roller is subjected to impact load repeatedly as it strikes the

sprocket teeth during chain engagement with the sprocket. After

engagement with the sprocket, equilibrium position of gear engagement

changes depending on tension. The roller, therefore, is subject to

stress load and friction when it is sandwiched between the gear and the

bushing and rotates over the tooth surface. It therefore requires shock

fatigue strength, proof compressive strength, and wear resistance.

RS11, 15, 25, and 35 chains do not have rollers. |

|

|

|

Two

bushings are press-fitted into two roller link plates so that the

roller can rotate outside the bushings. The same inner link is used for

both single and multi-strand chains. |

|

For

the outer link, two pins are press-fitted into two outer link plates.

For multi-strand roller chain, the middle plate is added to the pin

link. Slip fit middle plates are used for standard RS Roller Chain and

press fit middle plates for SUPER Roller Chain. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| The basic three

dimensions of roller chain are pitch, roller diameter, and inner link

inner width. The roller chain and the sprocket are dimensionally

interchangeable when the dimensions are identical. |

|

In a clearance fit,

the shaft and the hole will always have a space or clearance when

assembled. This occurs when the tolerance zone of the hole is

completely above that of the shaft (pin or bushing). |

|

In a press fit, the

shaft and the hole will always have interference when assembled. This

occurs when the tolerance zone of the hole is completely below that of

the shaft (pin or bushing). |

|

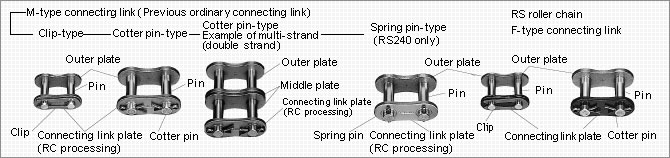

The spring clip, cotter pin, and spring pin are important parts in preventing the connecting link plate from

dislocating and maintaining chain strength. These parts must be assembled.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

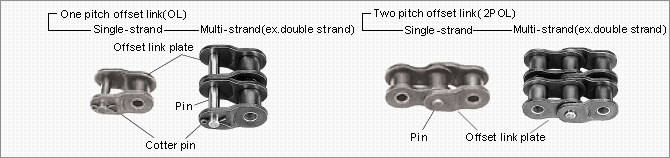

| Generally, roller chain is used either

endless with many links or fixed end. Both need a connecting link

(special connecting link for lifting). If the roller chain has an odd

number of links, an offset link can be used. The chain, however, must

be designed with even links when possible. |

|

|

|

|

|

|

|

|

|

|

|

|

|

For

the OL, make allowances for a decrease of 35% in kW rating (kW) and

maximum allowable load (kN {kgf}) compared to the chain itself. |

|

For the 2POL, the pin and the offset link plate are press-fitted and riveted, and can be used as per the kilowatt ratings table. |

|

|

|

|